PLM Implementation in Automotive Industry

Due to constant changes, the automotive industry, just like every other, has to be ready to respond to new market requirements and deliver new and more quality products faster.

That is when PLM steps into the scene. Thanks to product lifecycle management, the industry is building and delivering the next and improved generation of products that customers need. A new product introduction is one of the most important things when it comes to the company’s growth, and PLM can be a perfect solution for that. It will help you collect all the data, evaluate them, and, based on that, make a smart decision.

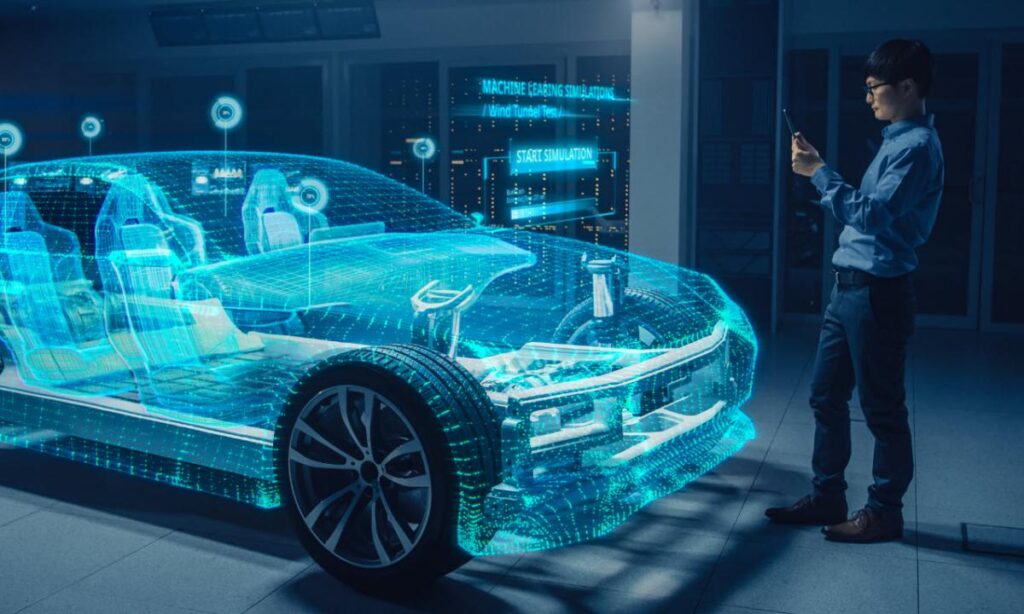

It has become a standard used strategic process in the automotive industry that has been embracing some of the latest PLM trends lately. Thanks to the use of digital thread and twin, the product’s performance and the product characteristics can be predicted, and based on the data from the real world, it is possible to see it in action, which is very valuable. Also, lately, the automotive industry is taking advantage of VR and AR, which allows producers to see how a certain part of a product in creating will work with some other parts and know what has to be modified. Microservices architecture has been present a lot as well because it allows a large number of applications to be divided into smaller parts that are easier to test and change. PLM is constantly changing and each new trend brings some new benefits that can be seen in action once they are implemented into the industry rightly.

Start Your Product’s Life With PLM

We are fully aware that digitalization is changing everything, and it is important to use the advantages of that process from the moment when the initial idea is born until the final disposal process to the customer. So, it is key to have a winning PLM strategy, which will start with great idea management and then move on to planning, designing, sourcing, manufacturing, etc.

If, and when, each step is done properly, as a result, you will get the final product that will meet everyone’s needs. PLM will guarantee that correct information is available at any moment, and chances of making mistakes will be minimized. Also, the development process will be faster. Your company will create profitable growth, thus the efficiency will increase, and overall productivity will improve.

How Can PLM Help Automotive Industry?

Automotive manufacturers are constantly finding new ways to make the automatization of the entire process better. That is why it comes as no surprise that the PLM platform is being more and more used nowadays. It can help integrate data, business systems, and all the people who are involved in the creation process.

One of the biggest benefits of PLM is that it allows you to develop huge and important innovations to the overall process. Companies will be able to communicate in real-time and be involved in each step of the product’s lifecycle.

The team will have in-depth knowledge about everything, which will eventually create a better workflow, and it will save a lot of time. The team will work and create more productively, which is for sure one of each company’s goals.

Besides that, PLM will for sure assist you with your profitability as well. Because you will be able to offer better quality products, you will be respected more in the market, and your products will have better value. That will eventually lead to better financial results. The offered products will be consistent in their style, they would become more recognizable, and all thanks to the smart use of PLM.

Of course, one of the most key features of each product is its quality. Because the valuable information is going to be shared with people with relevant opinions, the feedback will help improve everything that can be considered bad functioning. Due to centralized PLM solutions, the companies will make sure that each stage is managed the best way possible and the use of resources will be maximized.

This way the automotive industry will find and fix some important issues, and due to that, the customer experience will improve. Any defect will be detected on time, and not a single bad-quality product will be presented to the market. Thanks to PLM, the launch of each new product will be carefully arranged between all companies within the supply chain, using in the process up-to-date information which is available for use.

Product development is a very major step into the product lifecycle product, so increasing the efficiency of this aspect is crucial. The cost will be determined in the early stages, and products will be released sooner. Everyone in the team will have the same information, and based on that, they will know what is the next move. Companies will have better communications, but the customers will be updated as well all the time. Because of that, one PLM software is always needed to support products from creation until distribution.

Key Benefits of PLM in the Automotive Industry

The automotive industry has a few goals they are trying to reach. With great PLM by their side, doing that has never been easier. The companies are trying to avoid potential risks by using PLM systems, enabling cross-functional processes, responding more quickly to changes, updating more often to stay current, and, of course, as we have already mentioned, reducing costs. All of that, of course, while creating and distributing a top-notch product. The companies will have an insight into analytics, which will help them keep up with the entire product lifecycle.

The automotive industry is a complex structure of various logistic chains, suppliers being one of them. Standard PLM solutions, like Windchill and 3DEXP, are, among others, used by Tier 3, the suppliers of individual parts. Thanks to PLM, they are involved in the product development process together with vehicle manufacturers, and they can work in their environment. Different CAD solutions work within the same product which is very helpful, especially for product managers and architects who can follow the development of the parts supplied by Tier 3. That included even parts that are not made in-house, which is one of the biggest benefits. The manufacturers will receive parts that are customized to their specifications, assembled, and configured based on their requirements.

An in-depth understanding of PLM is principal for your business. Product lifecycle management is necessary for having a complete plan you can follow during the entire process. The products won’t become more innovative by themself, because a lot of effort has to be put into that creation.

It is very important to have a PLM professional by your side because dealing with each phase requires a lot of knowledge and experience. Firstly, the expert will determine which software fits you the best, and from there, your business will thrive. There are various stages of PLM, design, production, distribution, service, use, and, finally, recycling or disposal of a product. Only the true specialist will know how to handle each phase, and to get the best out of them. So, whenever you need a PLM genius, get in touch with our team. We will help you grow your business and gain more respect in the automotive industry.